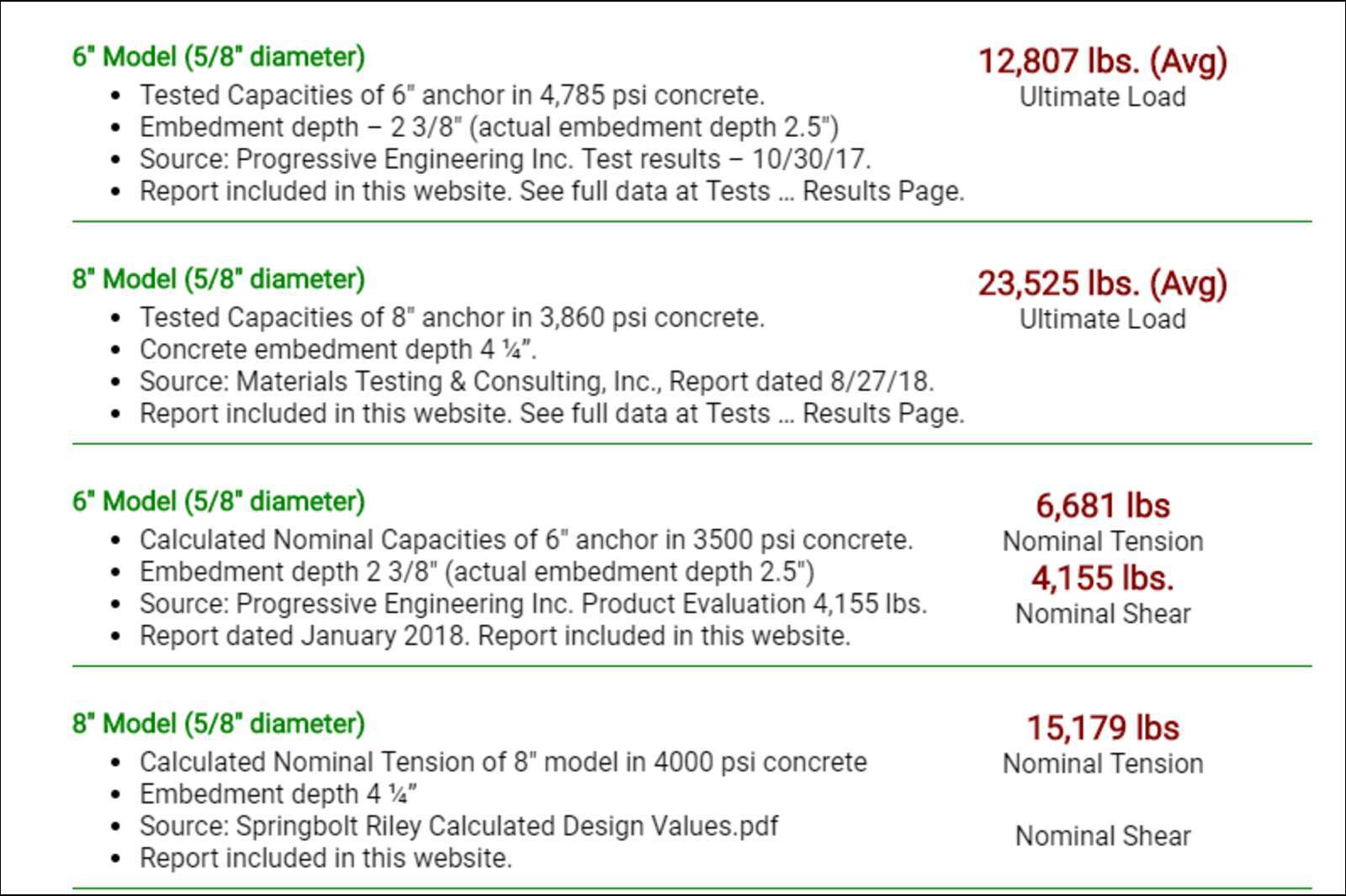

What We’re Solving The concept of the springbolt concrete anchor was conceived by the absence of a structural anchoring device that could be embedded in wet concrete thus eliminating the need for placement of an epoxy or wedge anchor. The springbolt concrete anchor, with its step design, can handle greater loads than other anchors. The advancement of GPS positioning contributed to the development of pre-installed anchor devices. The springbolt device can also be utilized to secure static loads or in earthquake areas to help protect structures from damage due to vibration. Cost VS Epoxy or Wedge Anchors Although the initial cost of the springbolt anchor may be more than an epoxy or wedge anchor, when all the costs of installation of epoxy or wedge anchors, e.g., drilling, epoxy insertion, tensioning and labor supervision are considered, the cost of a Springbolt is probably less.Additionally, once the Springbolt is placed, the concern for anchor failure is virtually eliminated because the aspects that affect epoxy and wedge anchors – vibration and climate – very rarely apply to the Springbolt. Failure Rate VS Epoxy or Wedge Anchors When failure is not an option Once the Springbolt is sized and placed, the concern for anchor failure is virtually eliminated. |

When Anchor Failure Is - NOT - An Option

Springbolt Concrete Anchor, LLC 4444 Sharpe Road Anacortes,WA 98221 Office: 360-941-0269 |